A wide array of bioactive compounds are synthesized in different concentration across different parts of the plant including leaves, roots, barks, fruits, flowers, seeds, stems and wood, oleoresin exudates, etc. [1]

The extraction procedure plays a crucial role in the final yield and phytochemical composition of the extract. Depending on the nature of the active substances to isolate, one procedure may be preferential than another one.

When the goal is to analyze the full crude extract of a plant for scientific purposes, the choice of the extraction procedure becomes even more critical. This ensures that specific compounds present in small amounts can be separated and identified from the crude mixture.

Additionally, certain plant constituents could also be particularly sensitive and degrade before they can be detected, making the selection of an appropriate extraction technique essential.

In fact, inadequate or overly aggressive extraction conditions can lead to the loss of bioactivity, altering the final chemical profile of the plant extract. Thermolabile compounds require gentle extraction techniques such as cold maceration or low-temperature distillation to avoid breakdown. On the other hand, robust compounds like alkaloids and saponins may tolerate harsher methods, such as Soxhlet extraction, which uses continuous recycling at elevated temperatures.

We will discuss this topic with Dr. Derek Osei Berchie, an interdisciplinary researcher conducting cutting-edge research at Brunel University’s Department of Chemical Engineering in collaboration with the College of Health, Medicine and Health Sciences.

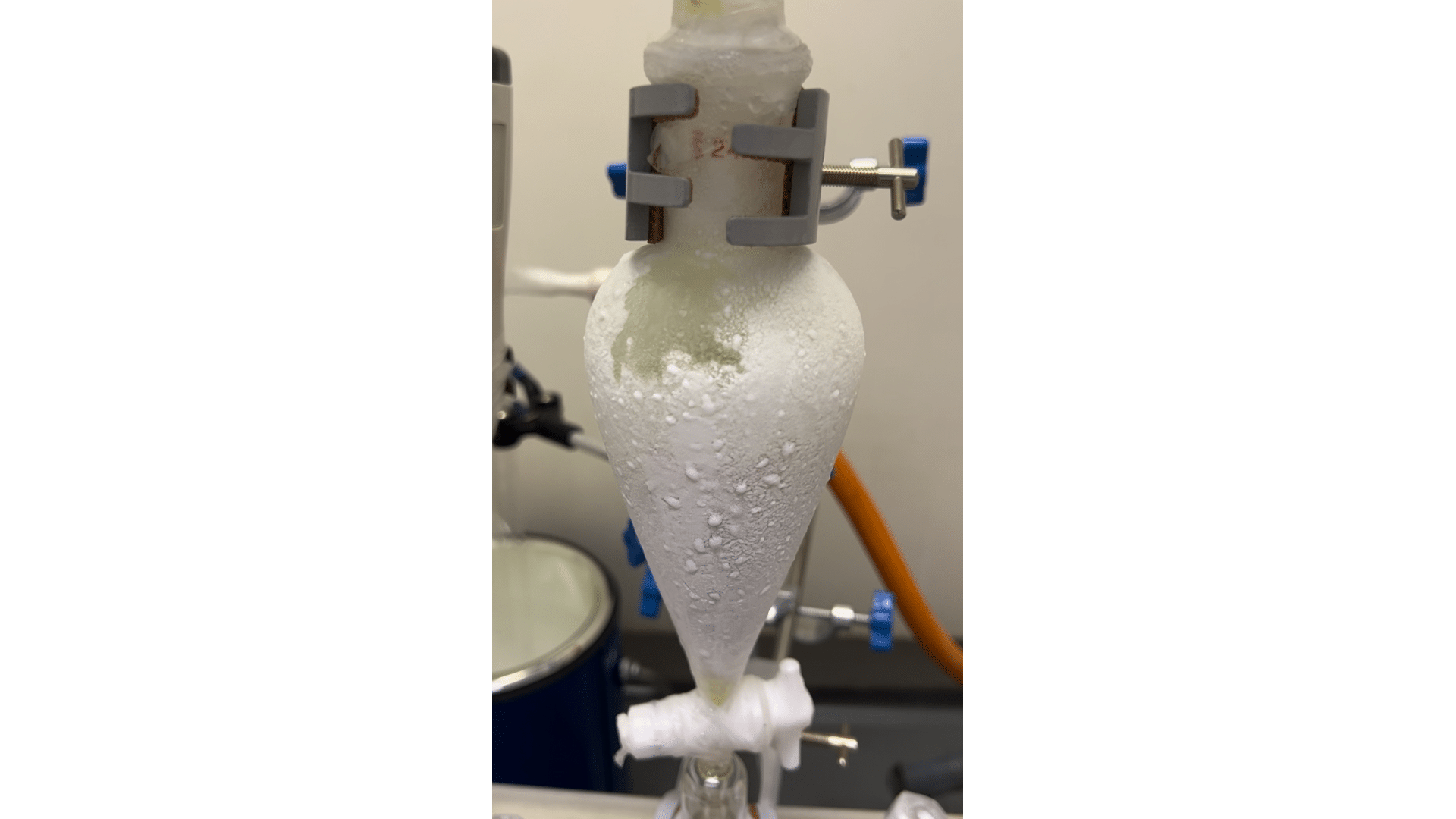

He developed and patented a simple self-agitated by vapor cryogenic low-pressure extraction procedure to overcome the limitations of conventional Soxhlet extraction.

This method, now developed employing basic laboratory glassware, shows great results for the extraction of thermolabile anti-cancer natural compounds that are often compromised by heat during conventional techniques. In fact the phytochemicals isolated with this method showed selective cytotoxic and potent cytostatic activity against malignant cells in vitro, proving the superior capacity of the cryogenic method compared to other techniques in preserving the bioactivity of the plant-derived components.

Even if for now the method developed by Dr. Berchie has seen application only in laboratory settings, it holds significant potential for large-scale application in industrial settings and its application could be useful for various industries ranging from pharmaceutical, to cosmetic and nutraceutical industries, where precision and compound preservation are paramount.

— What makes the extraction of bioactive compounds from plants such a complex and delicate process?

The extraction of plant bioactive compounds greatly considers the physicochemical properties of the compounds present in the plant matrix, especially that of the target compound(s). This mainly dictates the conditions required to separate the compounds from the plant matrix.

The extraction of plant bioactive compounds greatly considers the physicochemical properties of the compounds present in the plant matrix, especially that of the target compound(s). This mainly dictates the conditions required to separate the compounds from the plant matrix.

At times, the physicochemical characteristics of the target compound is unknown, making it difficult to predict the conditions required for extraction.

Additionally, the spectrum of compounds present in the plant matrix may consist of some compounds that express similar physicochemical characteristics to the target compounds, meaning that generalized methods can lead to the co-extraction of these unwanted compounds. The concentrations of the target compounds in the plant material are also relatively low, which further complicates the issue.

Here, more complex stepwise extraction regimes alongside process optimization studies may be required to enhance specificity and efficiency of the extraction process, with additional steps of purification to obtain sufficient amounts of extract of the desired purity.

Sometimes the necessary extraction conditions (to achieve sufficient amounts of extract with the desired purity) are also not always achievable with conventional methods, and may require some advanced or innovative extraction methods and regimes in order to execute the required process.

The advanced extraction methods typically adopt more elaborate mechanisms to influence the extraction process, and can be fine tuned over a broad range of operating parameters. This can enhance selectivity and efficiency of the extraction process, at a cost. Novel processes are developed to enhance the effectiveness and efficiency of a required extraction process at minimized costs.

Note, many bioactive phytochemicals express properties that make them sensitive to environmental conditions like heat, light, oxygen and upon exposure they can be degraded, chemically altered or evaporated away. When this is the case the required extraction conditions will minimize exposure to these factors so as to preserve the natural states of the desired bioactive compounds during extraction.

— Temperature and pressure play a crucial role in extraction processes. Why is it important to optimize these factors?

Temperature and pressures are factors that influence the rate of extraction. For heat stable bioactive phytochemicals such as many carotenoids and polyphenols, increasing temperature (up to a point) will increase the rate of extraction (considering all other extraction conditions are feasible and kept equal). Increased temperature generally increases extraction rate by increasing the solubility of phytochemicals in the solvent by supplying more kinetic energy, which boosts diffusion and mass transfer rates, and reduces solvent viscosity making the phytochemicals and solvent molecules more mobile (hence facilitating the movement of target phytochemicals from the plant matrix into the extract solution).

Temperature and pressures are factors that influence the rate of extraction. For heat stable bioactive phytochemicals such as many carotenoids and polyphenols, increasing temperature (up to a point) will increase the rate of extraction (considering all other extraction conditions are feasible and kept equal). Increased temperature generally increases extraction rate by increasing the solubility of phytochemicals in the solvent by supplying more kinetic energy, which boosts diffusion and mass transfer rates, and reduces solvent viscosity making the phytochemicals and solvent molecules more mobile (hence facilitating the movement of target phytochemicals from the plant matrix into the extract solution).

However, moderate to high temperatures can lead to the degradation of thermolabile (heat sensitive) phytochemicals and is costly. Pressure can be used to increase the density of the solvent to increase solubility and solvent permeability, by forcing solvent deeper into the plant particles. In combination at very specific ranges, temperature and pressure can also be used to achieve unique solvent properties such as supercritical fluids with both gas and liquid physicochemical properties (as with CO2), and can also be used to lower the solvent’s boiling point, which can optimize the selective extraction of thermolabile phytochemicals.

— How do you ensure that plant extracts maintain their potency and stability during and after the extraction process?

This requires careful consideration of factors that lead to evaporation, degradation and any other reactions that chemically alter the natural state of the bioactive compounds.

Deciding the appropriate extraction conditions and method able to execute these conditions in a controlled manner is important. Pretreatment, post extraction processes and storage must also consider to minimize the conditions that damage the extract bioactive components.

These damaging conditions (depending on the physicochemical properties of the target bioactive phytochemicals) include, heat, light, oxygen, type of solvent(s) etc., and are to be avoided or minimized to the required degree. Other conditions can help stabilize the bioactive phytochemicals such as an acidic solvent pH when extracting some polyphenols and flavonoids.

Adding some protective additives during extraction can also be helpful. Antioxidants like vitamin C, vitamin E can help prevent oxidation, as well as chelating agents such as citric acid can prevent metal ions from catalyzing degradative reactions.

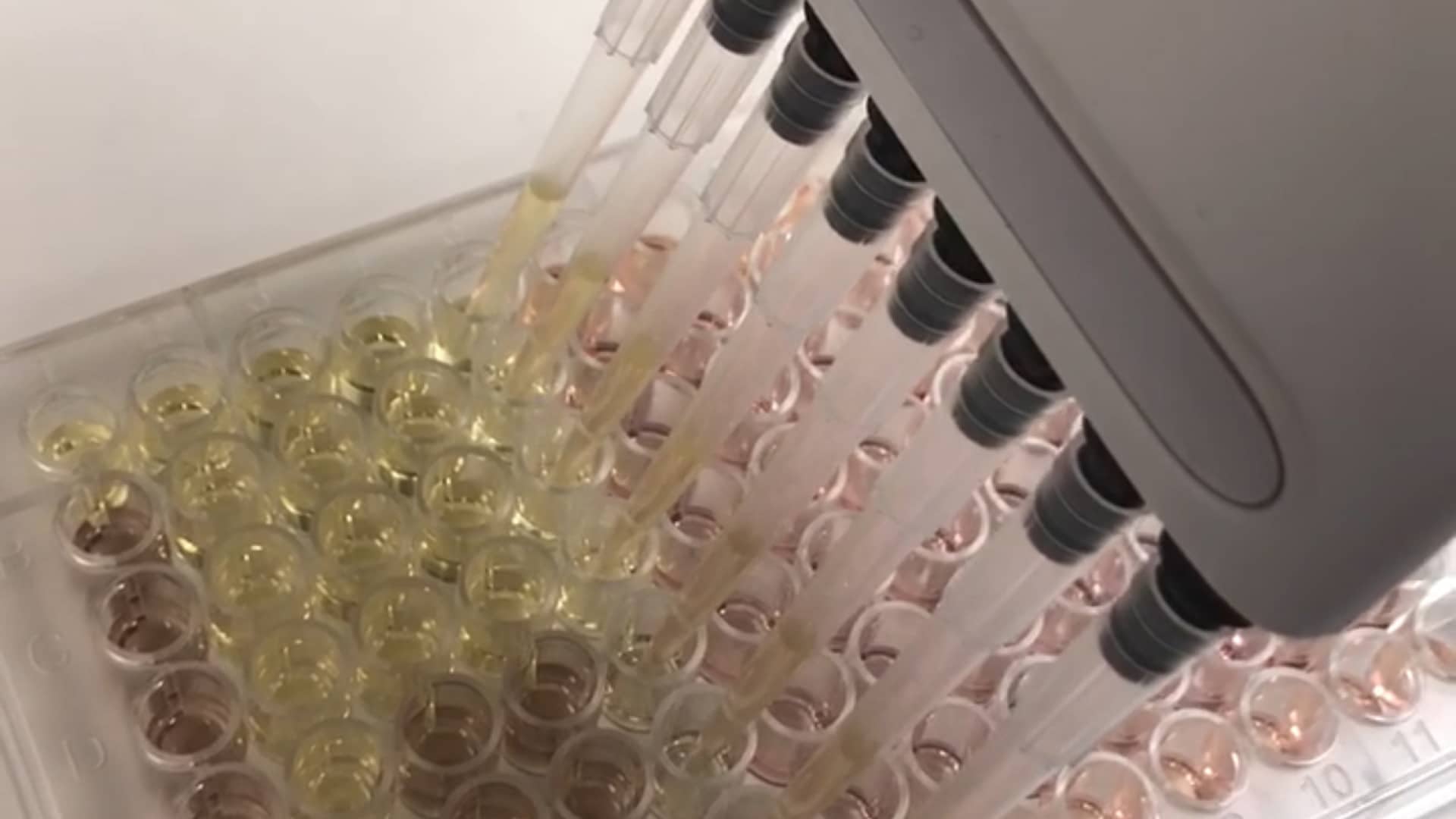

Ideally, some lab-scale analytical studies aimed to measure the effect of various aspects of pretreatment, extraction, post-processing and storage conditions on the bioactivity of the extract, alongside the optimum parameters is highly recommended. Regular chemical analysis and bioactivity testing over time as a monitoring regime is also good practice.

— In what ways can extraction techniques be optimized to handle larger-scale production while maintaining the integrity of the compounds?

This requires the optimization of operational parameters for bioactivity, choosing scalable extraction methods that can execute the required extraction conditions, and modifying the process to fit industrial purposes. Operational extraction parameters include, temperature, pressure, time, solid-solvent ratio, pH, particle size, moisture content, agitation rate, amongst others depending on the extraction method. Scalable extraction methods usually involve the advanced or innovative extraction methods (as opposed to conventional methods).

Having extraction processes that are highly controllable, efficient and effectively standardized to produce a consistent product is desired in industry.

Additionally, having integrated automation and real-time monitoring sensors, operating as a continuous mode process (as opposed to batch mode), having in-line filtration and purification systems, having validated handling and storage protocols, quality control protocols, and adopting environmentally friendly resources and practices, all address the desires of industrial scale extraction processes.

Industrial applications are very complex and well thought out with many factors to be considered including costs and any regulatory and compliance issues which can depend on the application of the product.

— When you developed your recently patented cryogenic extraction technique self-vapor agitated, which was the plant you were trying to extract?

I was researching Annona muricata L. (Graviola, Soursop) plant parts for the discovery of novel anti-cancer compounds (breast cancer). The plant has been shown to produce bioactive compounds that exhibit a range of bioactivities (anti-inflammatory, anti-hyperglycemic, anti-bacterial) where the acetogenins of this plant have been shown to have potent anti-cancer properties in-vitro and in-vivo (animal models). However, not all of the bioactive compounds from this plant have been characterized and studied for anticancer properties.

My aim was to isolate novel compounds that have potential in treating breast cancer. However, as the plant is widely studied I believe that many of the stable compounds are already characterized since they are easy to extract.

My approach was to target some of the compounds that are more difficult to extract and these are thermolabile and volatile.

Hence, I required low temperature (to protect against heat) vacuum (to protect against oxidation), with agitation (to enhance extraction rate) that was cheap and easily controlled. I have a background in design so I decided to innovate.

I tried many different modifications to conventional techniques and eventually came up with a design that met all the initial specifications. I have since extracted compounds from Graviola using the method and confirmed selective bioactivity of the extracts against breast cancer cells. I am currently working on validating a real time analytical method to monitor extractions, which I can then use to perform optimization studies at highly reduced costs. There is still a lot of work to be done!

— What are the primary advantages of your cryogenic extraction method over traditional techniques like Soxhlet extraction?

My technique utilizes operational conditions that the Soxhlet cannot, such as subzero temperatures and can also function at Soxhlet extraction temperatures. The range of operating temperatures spans from above the solvents freezing point to the solvent boiling point at atmospheric pressure. My technique also occurs under vacuum which removes air from the system and minimizes any potential oxidation of sensitive compounds, which the Soxhlet cannot. My technique has agitation (boosts extraction rate) which the Soxhlet does not.

My technique utilizes operational conditions that the Soxhlet cannot, such as subzero temperatures and can also function at Soxhlet extraction temperatures. The range of operating temperatures spans from above the solvents freezing point to the solvent boiling point at atmospheric pressure. My technique also occurs under vacuum which removes air from the system and minimizes any potential oxidation of sensitive compounds, which the Soxhlet cannot. My technique has agitation (boosts extraction rate) which the Soxhlet does not.

Hence, I can effectively create the physical conditions that suit the extraction of thermolabile and volatile compounds which the Soxhlet is not suited for. Additionally, in cryogenic mode I have immediate and perfect control over boiling (at low temperature) as I use pressure to vaporize the solvent and not heat, hence I can start and stop the extraction process almost immediately.

As heat is not used and does not involve hot boiling solvent my process is also safer in this respect than the Soxhlet (also as it is more controllable it is also safer in that respect).

The design of my technique can also allow for multiple functions including freeze-drying, extraction and concentrating extract to dryness all with one apparatus. Over other conventional techniques like maceration, cold percolation, the solvent consumption with my technique is much lower as I am able to recycle the solvent through more material.

— How crucial is interdisciplinary collaboration in improving extraction techniques for thermolabile compounds?

Extraction of thermolabile compounds requires a blend of expertise and I believe it is essential. Biologists validate the plant material and can validate the natural roles of the bioactive components.

Chemists have better understanding of the structural characteristics and degradative factors that affect the bioactive component. Chemical engineers (alongside mechanical and electrical engineers) can design the build the innovative extraction equipment with the required automation, controls and sensors alongside optimizing the operational parameters.

Food and pharmaceutical scientists can ensure extract integrity throughout and after the extraction process with their analytical methods alongside biological scientists who can assay more advanced bioactive properties.

Material scientists can work on the novel stabilization techniques to maintain the integrity of the thermolabile compounds (nanoparticle encapsulation), environmental scientists can advise on sustainable practices, tech specialists implement machine learning algorithms and digital model into the process, biotechnology can address factors that increase concentrations of the desired compounds in the plant and so forth.

The whole field of natural products extraction, especially of particular categories of compounds is very important to allow the efficient and effective translation of analytical and semi-preparative lab scale studies into cost effective, eco-friendly high-quality commercial products that can advance human health and wellbeing.

— Are there any plant species you’ve encountered in your research that you believe hold unexplored potential for bioactive compound extraction?

Yes, Trema micrantha and Trema orientalis, have been reported to contain understudied and it would be interesting to investigate the medicinal value of these plants.

Vernonia amygdalina just sounds wonderful but has been reported to be ingested by chimpanzees when suffering parasitic infections. Note that less than 10% of natural phytochemicals have been accessed for bioactivity so the list can be endless. Usually researchers are directed by traditional practices and observations of the natural world.

— With the rise of natural products and green chemistry, how do you see the demand for plant-based extractions evolving in the coming years?

As new emerging ‘green’ technologies are developed that allow the investigation and harnessing of more and more natural plant-based products that continue to improve human health and wellbeing, alongside the negative health effects and environmental impact of synthetic compounds are realized, I believe there is ever increasing demand for natural products of which the plant-based form a large proportion of.

The increase demand for plant-based products will increase the demand of innovative extraction solutions to capitalize on the growing market.

— What advice would you give to young researchers entering the field of natural product extraction?

I would say, have ideas and be excited to try them out, you can be wrong 1000 times but you only have to be right once. There is so much that is unexplored in nature, there are always new pastures to explore, and your work can make a huge difference to literally the whole world. We all contribute in our small way, and collectively we can make earth smile.

On a technical level, make sure you understand the basics and fundamental principles very well, stay up to date on all the new techniques, focus on sustainability, learn just as much from related interdisciplinary fields (also network and collaborate), and lastly enjoy what you do.

References:

[1] Fongang Fosting et al. , Extraction of Bioactive Compounds from Medicinal Plants and Herbs; pharmacognosy – medicinal plants, 2021 10.5772/intechopen.98602